ASUS ROG Maximus X Apex Demonstrates World-Beating Performance

ROG is obsessed with chasing the highest overclocks and fastest performance. We take these pursuits so seriously that our engineers created a series of Apex motherboards specifically for setting records. The first iteration appeared in the Maximus IX family for Z270 and broke both frequency and benchmark records for Kaby Lake CPUs. Now, its Maximus X Apex successor has arrived with Z370 and Coffee Lake. Our in-house experts have been hard at work setting new records that cement the Apex’s status as the top overclocking motherboard for Intel processors.

Meet the Maximus X Apex

Before we get into the records, it’s worth taking a moment to introduce the board. Although the Apex arrives as part a new Maximus X family, you can easily pick it out from the crowd. The unique X-shaped PCB stands out visually even without the RGB lighting that glows behind its cut-out edges. Aura Sync backlighting extends to a customizable nameplate in the center of the board, and you can illuminate an entire system via four onboard headers for LED strips.

ROG-Maximus-X-Apex-2D-1-Aura-2

Closer inspection reveals the Maximus X Apex’s extreme overclocking aspirations. Dual 8-pin connectors supply extra power to the CPU, voltage probing points stand ready for multimeter monitoring, and special LN2 modes adapt to sub-zero cooling. To prevent liquid-nitrogen vapor from disrupting your view at a critical moment, we’ve added a fan bracket to the I/O heatsink, plus extra headers for full-speed fans, so you can easily direct airflow toward your pot.

Another clue to the Apex’s mission lies in the dual-DIMM layout, which has half as many slots as typical Z370 boards. The traces can be more direct with only one DIMM per memory channel, leading to improved signaling that improves DRAM stability and increases overclocking headroom. The extra slot next to the DRAM is for our DIMM.2 module; it can hold two NVMe SSDs along with dedicated fans to keep drives from throttling under heavy sustained loads. We even pushed performance on the networking front with a wired 5G NIC that blows past Gigabit Ethernet speeds.

Extreme preparation

It’s customary for us to fly in a few well-known overclockers to help put a new platform through its paces. Usually, we share the results of these endeavors without detailing the background work required to obtain the scores. However, in case all of this comes across as being too easy, we’ve decided to share some of the details with you.

While the Apex provides the perfect foundation for breaking performance records, the accompanying hardware also needs to be up to the task. The overclocking capabilities of CPUs and memory modules vary from sample to sample, so the hardware needs to be hand-picked. It’s a time-consuming process that requires multiple stages of evaluation.

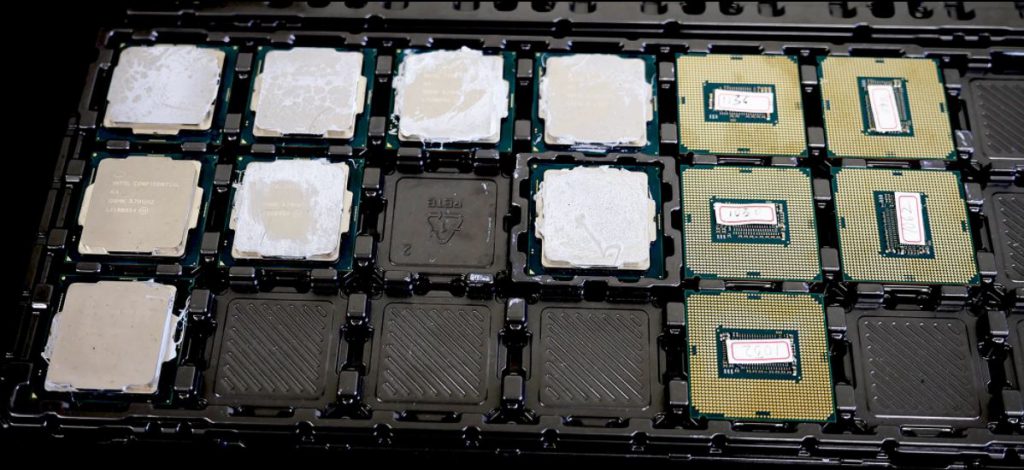

The first step involves binning CPUs by using air cooling and subjecting them to a multi-threaded benchmark (Cinebench) at a frequency and voltage (Vcore) that weeds out the stragglers. This process nets the top 10-15% of samples, which are then re-tested to check how Vcore requirements scale as clock frequencies increase.

With initial data obtained, CPUs are de-lidded to replace the stock thermal interface material (TIM). TIM choice is critical because the compound needs to be malleable enough to cope with the contraction and expansion of surfaces during extreme benchmarking. Eventual fractures are inevitable, but some materials perform better than others in this regard. Application methods are also a far cry from the conservative, rice-grain-sized amount required for conventional setups. A liberal quantity of paste is spread over the die and surrounding PCB to reduce the chances of dreaded ‘paste crack’ and to help improve thermal transfer.

der8auer readying a CPU for cryogenic cooling

Binned CPUs are then subjected to liquid nitrogen (LN2) cooling, noting maximum operating frequencies and required voltages to pass a multi-threaded benchmark. Usually, a few samples will exhibit quirks when cooled past a certain temperature. With Coffee Lake, the issues aren’t severe, as CPUs can POST at temperatures that are close enough to the cooling limit of LN2 (-180 – 190°C). At worst, CPUs need to be ‘warmed’ to -150°C to work around the dreaded ‘cold-boot bug.’ To some extent, this also helps reduce chances of the TIM cracking due to thermal cycling. Of course, there’s still a risk of fracture when running multi-threaded benchmarks because the TIM has to transfer hundreds of watts of heat, which causes a large temperature delta between the die and integrated heat spreader. The temperature disparity can result in the rapid expansion and contraction of those surfaces, a prime recipe for paste fracture. When fractures occur, they can sometimes be fixed by warming the LN2 pot to positive temps. If that doesn’t work, the rig has to be dismantled to replace the TIM. Although the situation is far from desirable, it’s an accepted facet of extreme overclocking.

Binning memory is even more complex and time-consuming than finding good CPUs. As with processors, memory modules are sorted in multiple stages. Some of the sorting practices are a closely guarded secret, involving everything from tuning latencies to evaluating capabilities with tweaked software. Needless to say, we can’t share all of the juicy details with you. But we can provide a brief overview detailing the target parameters and some of the pain points.

While the current ICs of choice for extreme overclocking–Samsung B-die–don’t need to be chilled to cryogenic temps, good modules deliver optimal latencies when kept within the region of 5-20 Celsius. The target parameters to break world records are DDR4-4200 at 12-11-11-28 timings. To give an example of how low these latencies are, high-performance memory kits rated at this frequency are usually clocked at 19-19-19-39 timings. Naturally, most modules we test don’t meet our requirements. Even when they do, required voltages can vary, making it extremely difficult to find a matching set.

And this brings us back to the Apex. Achieving such latencies at DDR4-4200 isn’t possible on conventional motherboards, but the Apex’s highly optimized two-DIMM layout and tuned firmware make it possible. At the same time, CPU power delivery needs to be robust enough to run benchmarks at high clock speeds. When overclocked to 6.5GHz, a 6-core Coffee-Lake CPU can draw in excess of 600 watts under full load, and the Apex’s 8-phase power solution is more than up to the task. This over-engineering pays dividends for conventional cooling, too. A motherboard that’s tuned to achieve these feats is more stable, making it a better choice if you intend to push the platform with less exotic cooling.

The data we obtain from the binning process is also of interest for ambient cooling. Our Coffee Lake testing revealed that 50% of early 6-core CPUs can achieve 5GHz with water cooling. If retail CPUs achieve the same, it shows Intel’s mastery of the 14-nm process. Compared to Kaby Lake, we’re getting two extra cores and better power efficiency without sacrificing overclocking potential. If everything comes together with final chips, Coffee Lake could set new overclocking standards for mainstream desktops.

Binned and ready for extreme abuse

With the binning process complete and a handful of promising CPUs at our disposal, we invited a few renowned overclockers to test the limits of the Z370 platform.

Alex@ro, elmor, der8auer, Rsannino, shamino

Pushing the limits of the i7-8700K

From an extreme overclocking perspective, obtaining a CPU frequency validation is practically mandatory. We have a long-standing tradition to uphold, with generations of ROG motherboards holding frequency world records with different CPUs.

The Maximus X Apex didn’t disappoint with Coffee Lake. Extreme overclocker der8auer was able to save a Core i7-8700K validation at 7.3GHz on all 6 cores and 12 threads. That’s double the 3.7GHz base frequency of the processor.

As stated earlier, the Apex is tuned to deliver maximum memory performance rather than just raw CPU frequency. Our in-house overclockers decided to take a stab at the current memory frequency world record, and they managed to break it with an 8GB G.Skill DDR4 module clocked at 5529.2MHz using 24-31-31-63-3 (CAS-tRC-tRP-tRAS-CR) timings.

We didn’t just concentrate on frequency records. The table below shows the full gamut of top scores set by the Maximus X Apex teamed with the i7-8700K, along with the CPU clock for each score.

Aside from 3DMark06, all of the new scores bested previous results set on the X299 platform with an i7-7800X CPU. That’s because the Skylake-X CPUs use Intel’s fully integrated voltage regulator, which makes them intolerant of temperatures colder than -100°C. In contrast, Coffee Lake processors rely on conventional power delivery and are capable of running at the limits of liquid nitrogen cooling (-186°C). On both architectures, a 10 Celsius drop in temperatures improves overclocking headroom by at least 100MHz. Limited to -100°C, Skylake-X CPUs top out at 6GHz. Better tolerance for extreme cryogenic temperatures gives Coffee Lake CPUs a 1GHz advantage in peak clock speeds.